Views

Views

These tools are known as '7 New Management and Planning Tools' and used by Six Sigma professionals for qualitative data analysis. This video gives you a brief introduction of all New 7 QC Tools.

28,160

From Embeds

Number of Embeds

ActionsDownloads

Comments

Likes

7 Qc Tools Pdf 2017

Embeds 0

New 7 Qc Tools Quality Management

7 Qc Tools Pdf

-

-

New 7 QC Tools

History of the New 7 QC Tools Slide 1 0f 2

Committee* of J.U.S.E. - 1972 Aim was to develop more QC techniques with design approach Work in conjunction with original Basic Seven Tools New set of methods (N7) - 1977

-

-1

-

-

History of the New 7 QC Tools Slide 2 0f 2

!'

#

$

% &'( ( $

*##

+,

- .

/) ' 52

7 ,22 -%$3 $4 + + 2 3. 5 $ , 5-%$. 2. & ' & ( (, 6 3 $ 7 5 $ %

- 6

- 6 7 ,22 6 # + + 6 , 6 '

%&

-%$ 6

-%$ 2 & 6 ' )

3+ $ 2 3.-%$ .8 ,22 (Design Approach) #5

.5

4

#

- 96

TQM

New 7 QC Tools : Part I - Introduction What are the New 7 QC Tools? Affinity Diagrams Relations Diagrams Tree Diagrams Matrix Diagrams Arrow Diagrams Process Decision Program Charts Matrix Data Analysis

-

-2

-

-

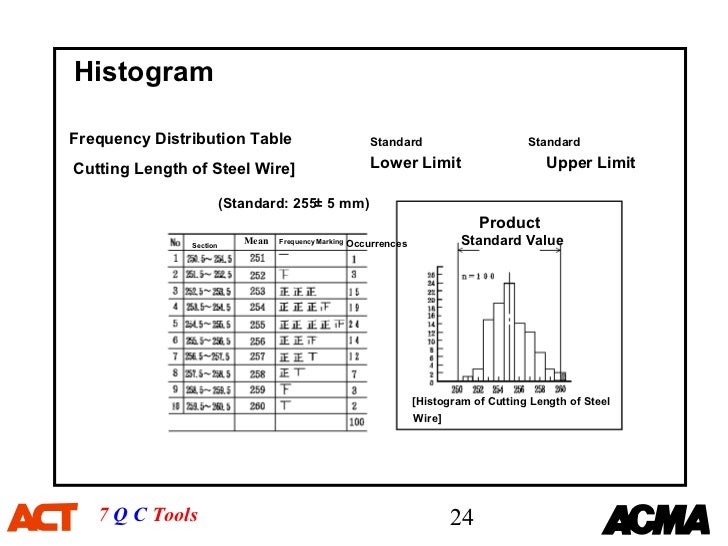

New 7 QC Tools : Part I - Introduction What are the Basic 7 QC Tools ? Flow Charts

Run Charts Histograms Pareto Diagrams Cause and Effect Diagrams Scatter Diagrams Control Charts

New 7 QC Tools : Part I - Introduction '! ' # # .J9

$ #

#

*

.J9

The Basic 7 Tools •(

*

% 6

*

The New 7 Tools • ( • %

'

()

& Source: Nayatani, Y., The Seven New QC Tools (Tokyo, Japan, 3A Corporation, 1984)

-

-3

-

-

New 7 QC Tools : Part I - Introduction

5-Gen ' (

+,-.

Genba Genbutsu Genjisu Genri Gensoku

/

,' !' ' 012, ,/ $ # 3 4 $

# )# ( -5+ (#*-

# -

New 7 QC Tools : Part I - Introduction

# # /

/6 !' ,7 $' ($ 7 7 %

,

!

' *

8 - * -

# !' % #

-

# # #

-

/$

/6 $ (Sample) , ( $ 8 - * (Population) ,

'

-4

-

-

New 7 QC Tools : Part I - Introduction # $ $ *

- , , () /7 ) )

#

$ (Continuous)

(Discrete)

New 7 QC Tools : Part I - Introduction

/$ ,1: (

/6

%

# , (

!' (#* # 3

,2: * #,

% *

/$, # (#*

$,

-

-5

-

-

New 7 QC Tools : Part I - Introduction # , -9 - *: # 1 * % / $ Accuracy ( Relevant $ - * ! Timeliness $ #

New 7 QC Tools : Part I - Introduction

$/- *

!

(#*$ $ )# * )#$ * $ $ ' 3 , '*

-

# 8'*$ ' (#*$ , - *:

#

* 7

8 #

, $/- * ; *$ % # 3 7--2 $'6

-6

-

-

New 7 QC Tools : Part I - Introduction

% $

%

*7 - 7 $ ,

#* #

6

!

' - * # '* ! / % 7* )# 7 '% ( - * # ' * , $ '* % ( # , 7

#

'

! #7' &6 1

, #($

New 7 QC Tools : Part I - Introduction (

$ % -5+ - () KJ - () IR - () - () - () )

- ()

-

*'

$(#* , 7 $ < *

() (#* - () PDPC

$/- *

%

( 7

# $

$

:$7-

# &

-7

-

-

New 7 QC Tools : Part I - Introduction

-5+ ($ $ 7

,

36 '

,

New 7 QC Tools : Part I - Introduction

-5+ $ ,

,'$

( '

,

,

( 7 7# $$ '$

$7 / # ) # #

-

7

#

3

-8

-

-

New 7 QC Tools : Part I - Introduction

() ) # : (Affinity Diagram) =

:

Dr. Jiro kawakita % -5+ / , ' (#* ' % ( ( ( -9

# ( :

(Chaotic Situation) $7 (Concept Design)

-

New 7 QC Tools

History of the New 7 QC Tools Slide 1 0f 2

Committee* of J.U.S.E. - 1972 Aim was to develop more QC techniques with design approach Work in conjunction with original Basic Seven Tools New set of methods (N7) - 1977

-

-1

-

-

History of the New 7 QC Tools Slide 2 0f 2

!'

#

$

% &'( ( $

*##

+,

- .

/) ' 52

7 ,22 -%$3 $4 + + 2 3. 5 $ , 5-%$. 2. & ' & ( (, 6 3 $ 7 5 $ %

- 6

- 6 7 ,22 6 # + + 6 , 6 '

%&

-%$ 6

-%$ 2 & 6 ' )

3+ $ 2 3.-%$ .8 ,22 (Design Approach) #5

.5

4

#

- 96

TQM

New 7 QC Tools : Part I - Introduction What are the New 7 QC Tools? Affinity Diagrams Relations Diagrams Tree Diagrams Matrix Diagrams Arrow Diagrams Process Decision Program Charts Matrix Data Analysis

-

-2

-

-

New 7 QC Tools : Part I - Introduction What are the Basic 7 QC Tools ? Flow Charts

Run Charts Histograms Pareto Diagrams Cause and Effect Diagrams Scatter Diagrams Control Charts

New 7 QC Tools : Part I - Introduction '! ' # # .J9

$ #

#

*

.J9

The Basic 7 Tools •(

*

% 6

*

The New 7 Tools • ( • %

'

()

& Source: Nayatani, Y., The Seven New QC Tools (Tokyo, Japan, 3A Corporation, 1984)

-

-3

-

-

New 7 QC Tools : Part I - Introduction

5-Gen ' (

+,-.

Genba Genbutsu Genjisu Genri Gensoku

/

,' !' ' 012, ,/ $ # 3 4 $

# )# ( -5+ (#*-

# -

New 7 QC Tools : Part I - Introduction

# # /

/6 !' ,7 $' ($ 7 7 %

,

!

' *

8 - * -

# !' % #

-

# # #

-

/$

/6 $ (Sample) , ( $ 8 - * (Population) ,

'

-4

-

-

New 7 QC Tools : Part I - Introduction # $ $ *

- , , () /7 ) )

#

$ (Continuous)

(Discrete)

New 7 QC Tools : Part I - Introduction

/$ ,1: (

/6

%

# , (

!' (#* # 3

,2: * #,

% *

/$, # (#*

$,

-

-5

-

-

New 7 QC Tools : Part I - Introduction # , -9 - *: # 1 * % / $ Accuracy ( Relevant $ - * ! Timeliness $ #

New 7 QC Tools : Part I - Introduction

$/- *

!

(#*$ $ )# * )#$ * $ $ ' 3 , '*

-

# 8'*$ ' (#*$ , - *:

#

* 7

8 #

, $/- * ; *$ % # 3 7--2 $'6

-6

-

-

New 7 QC Tools : Part I - Introduction

% $

%

*7 - 7 $ ,

#* #

6

!

' - * # '* ! / % 7* )# 7 '% ( - * # ' * , $ '* % ( # , 7

#

'

! #7' &6 1

, #($

New 7 QC Tools : Part I - Introduction (

$ % -5+ - () KJ - () IR - () - () - () )

- ()

-

*'

$(#* , 7 $ < *

() (#* - () PDPC

$/- *

%

( 7

# $

$

:$7-

# &

-7

-

-

New 7 QC Tools : Part I - Introduction

-5+ ($ $ 7

,

36 '

,

New 7 QC Tools : Part I - Introduction

-5+ $ ,

,'$

( '

,

,

( 7 7# $$ '$

$7 / # ) # #

-

7

#

3

-8

-

-

New 7 QC Tools : Part I - Introduction

() ) # : (Affinity Diagram) =

:

Dr. Jiro kawakita % -5+ / , ' (#* ' % ( ( ( -9

# ( :

(Chaotic Situation) $7 (Concept Design)